Maersk Fluid Technology (MFT) said it has recently upgraded its SEA-Mate Blending-on-Board Value Calculator to include a mobile optimized version that will assist in calculating savings, based on a variety of real life scenarios.

The SEA-Mate Blending-on-Board (BOB) system enables the crew on board the vessel to blend an engine-specific fit-for-purpose cylinder lubricant with the optimal neutralization and detergent properties. The in-use two-stroke engine system oil is blended with a high-BN cylinder oil. The resulting fit-for-purpose cylinder lubricant composition matches actual engine operating conditions and fuel sulphur levels, making it possible to reduce cylinder oil consumption and mitigate issues like cold corrosion and excessive cylinder wear.

Under traditional running conditions, no regular consumption of a two-stroke engine’s system oil takes place. Its additives are depleted and viscosity increases over time. As BOB generates a consumption of the in-use system oil, the crank case oil is replenished with fresh oil with fresh anti-wear and detergent additives etc. And as the refreshment becomes a reoccurring event, system oil viscosity is returned to its original state, reducing friction in the engine and thereby providing proven fuel savings up to 1.5 percent.

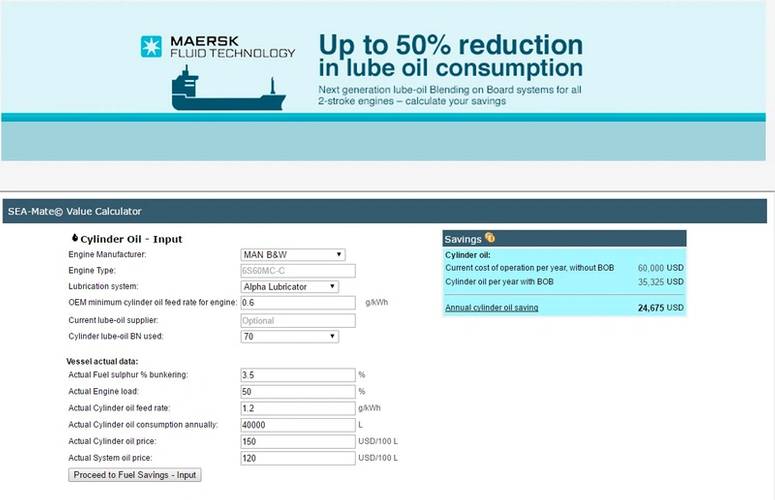

The SEA-Mate Blending-on-Board Value Calculator allows customers to evaluate the different potential savings with their engine and running conditions in mind, and a vessel-specific savings potential report is generated. The report highlights potential cylinder oil savings, as well as energy and consumption savings related to having a continuous refreshment of the system oil. Calculations are on actual system and cylinder oil consumption and cost for both main engine and auxiliary engines. It also includes an estimate for expected reduction of maintenance cost – reduced cost for change of cylinder piston rings and liners, reduced cost for purifier maintenance and more. The resulting report is emailed to the customer’s inbox for further evaluation and support when building a business case.

Sune Lilbaek, Head of Sales at Maersk Fluid Technology, explained, “By using the value calculator it is easy to see the potential cost savings achievable with the introduction of a BOB system. With over 200 installations to date, we have proven it is possible to achieve lubrication at, or close to, the lowest allowed consumption of lubricant as specified by the engine manufacturer. This results in proven reductions of up to 40 percent in two-stroke engine cylinder oil consumption, as well as significant fuel and maintenance savings.