Engineering specialists at Caterpillar Marine’s new Marine Solutions Center are overseeing delivery of the first Cat Marine Hybrid Thruster system, being delivered this month to an undisclosed shipyard in Singapore and will be commissioned midyear.

Caterpillar Marine said the new propulsion setup outperforms diesel mechanical systems in all partial load conditions, and offers improved fuel economy and substantial through-life savings for a variety of offshore support vessels (OSV). For vessels spending a high amount of time in standby or DP service, the annual fuel savings can be as high as 35 percent, calculated across the entire operating profile of the vessel.

The performance achievements are the result of Caterpillar’s holistic approach to optimizing vessel operations and reduced total cost of ownership for owners. Typically, the Cat Marine Hybrid Thruster system could be used to downsize a vessel’s main engine so that engine load is optimized, while also allowing the vessel to switch to diesel electric mode for low DP operations or in standby.

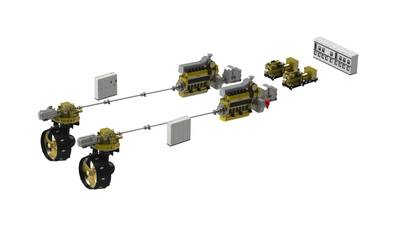

For example, a standard 7,000 hp standby support vessel featuring conventional powering would require 2x MaK 8 M25 C main engines at 2,666kW at 750rpm and a pair of cat C18 gensets. With the new Cat hybrid thruster system the same vessel could instead use smaller 6 M 25 C main engines at 2,000kW at 750, and two booster motors mounted on the back of the Cat MTA 730 CP azimuth thrusters powered by twin Cat C32 generator sets. The booster motors and drives are controlled directly from the Caterpillar MPC 800A control system which also performs all mode selections, interfaces with the vessel’s PMS and provides a single point interface for the operator.

Caterpillar Marine believes that the Cat Marine Hybrid Thruster represents a significant new market contender, either for retrofit or installation at newbuild stage. In transit operations and in diesel-mechanical mode, the smaller engines run at higher loads, consuming less fuel. In low-speed transit, either one or two gensets can power the main azimuth thruster in diesel-electric mode giving typical fuel savings of 10-15 percent at speeds in the 7-9 knots range, depending on hull profile. However, the biggest savings are made during standby and DP operations where the vessel would operate in diesel electric mode with the main azimuth propellers running in the most efficient variable speed mode.