Efficiency Gains from Eliminating the Hub Vortex

There is hydrodynamic solution that delivers multiple benefits for ship owners facing increasingly tough regulatory requirements and rising operational costs, writes Dr. Batuhan Aktas*

One area of ship operations that has attracted much attention in recent years due to the possibilities it represents for emissions reduction is that of cavitation. During ship operations, cavitation occurs because of vortices that build up and cause bubbles to collapse under the ship’s propeller. The results of this process include increased noise, vibration and energy usage. The latter is of particular concern for ships looking to streamline their energy profile.

Existing energy saving designs for propeller hub caps or boss caps incorporate fins that act to improve vessel efficiency by reducing cavitation while ships are at sea. However, the finned design generates turbulence and is linked to cavitation as bubbles form underwater.

At EcoMarine Innovations, a start-up supported by the University of Strathclyde, we set ourselves the goal of addressing these issues while we were working on a project with a major European propeller manufacturer. During this collaboration, we learned that cavitation is a major cause of inefficient ship operations, accounting for 3-8% of lost propulsive efficiency.

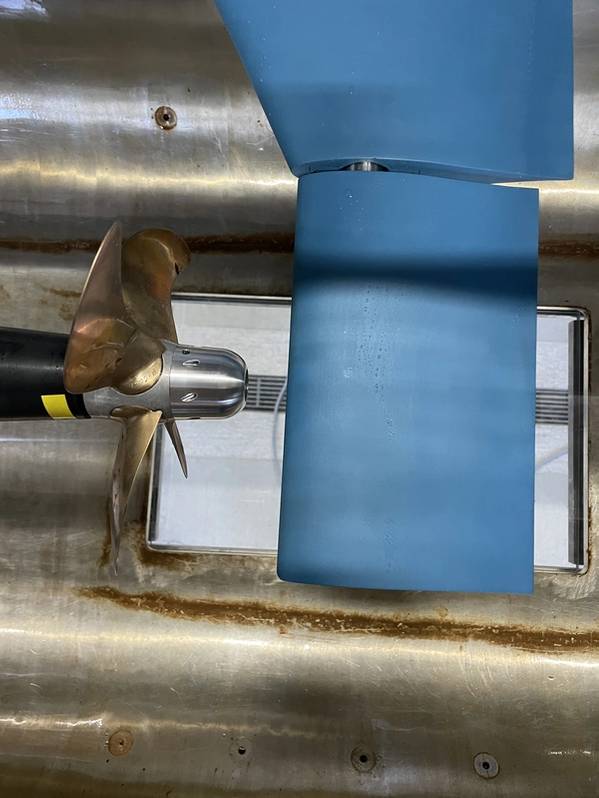

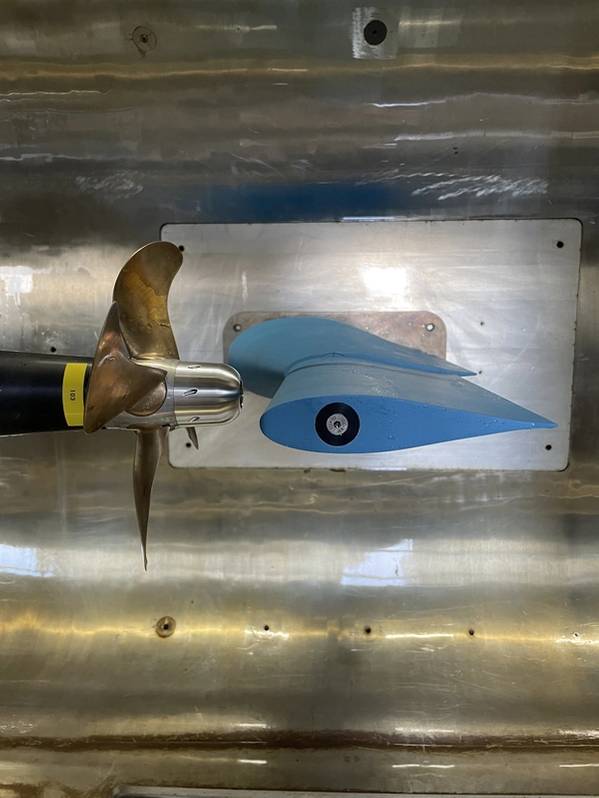

Convinced that it must be possible to develop a better way of addressing this efficiency cost and the related environmental impacts, we studied the design of boss caps commonly used on ships. In the course of this research, we began exploring the idea of designing a boss cap that uses holes instead of any structure that can cause turbulence or operational risk. The result is the Holy Boss Cap (HBC). Holy Boss Cap undergoing trials.

Holy Boss Cap undergoing trials.

Image courtesy EcoMarine Innovations

Holy Boss Cap undergoing trials.

Holy Boss Cap undergoing trials.

Image courtesy EcoMarine Innovations

Testing the Tech

The development of the HBC demonstrates the importance of research support of the kind we have at Strathclyde University. The product, which was launched in February 2024, eliminates propeller hub vortex cavitation, the main source of rudder erosion, and reduces associated propeller efficiency losses. However, an early version of the innovative ‘holy’ design failed to gain traction as it was not hydrodynamically efficient, as the holes reduced the efficiency of the propeller.

The revised design of the HBC, which we implemented following extensive studies in partnership with the University, addressed these problems with carefully placed and angled holes bored into a conically shaped hub. The holes channelled into the hub affect the high pressure in the hub vortex by redirecting the flow downstream. The resulting low-pressure swirl flows in the opposite direction to conventional hubs, behind the propeller blades, reducing propulsive drag, fuel consumption and maintenance costs.

To assess the effectiveness of the new design, we carried out computational fluid dynamic (CFD) tests on a typical twin-screw vessel with V-brackets and a 90m coastal general cargo ship. Using local workstations running parametric optimization software combined with CFD software, we studied the effects of variables such as chamber volume and profile, number of holes, and angle of the holes.

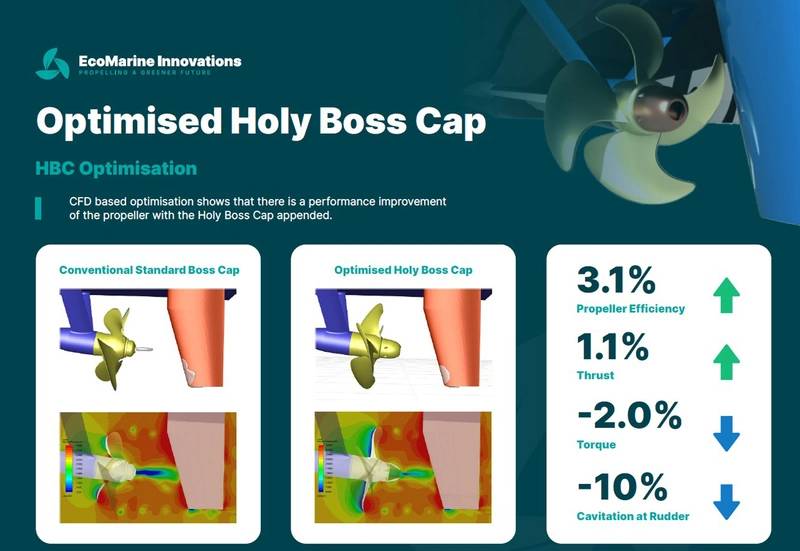

When we compared the HBC with more advanced energy-efficient boss caps currently in operation, we found that it to be at least 3% more efficient. Overall, compared to standard propeller boss caps, the HBC improved propeller efficiency by 3.1% and thrust by 1.1%, while reducing torque by 2%, rudder cavitation by 10%, and propeller induced noise by 1-3dB. We expect the HBC to be capable of delivering increases in propulsion efficiency of up to 5%, compared to conventional propeller boss caps.

These potential savings were further confirmed by a European cavitation tunnel testing facility, where savings more than 2.1% were found despite challenging scale effects.

Given the pressing emissions-reduction challenges that the shipping sector faces, we believe it is not enough to develop a solution without ensuring that it can be scaled in a meaningful way. Having successfully completed validation tests at a hydrodynamic research centre in Sweden, the HBC is undergoing ship model basin trials to verify the efficiency gains on larger commercial and naval vessels. Meanwhile, the patent for the HBC is pending, with the support of Strathclyde University in the patent application process.

Image courtesy EcoMarine InnovationsA Simpler Solution

Image courtesy EcoMarine InnovationsA Simpler Solution

It has become clear to us while developing the HBC that traditional methods of addressing ships’ energy wastage have failed to keep pace with the industry’s needs, or to consider the wider impacts of underwater noise and vibration. Zero propeller hub vortex cavitation can help towards ESG, EEXI and CII goals, improve efficiency and reduce the costs associated with cavitation induced rudder erosion. Driven by research, the HBC is meeting this need in the market and is contributing to more sustainable ship operations.

Underpinning our efforts in bringing this product to market is the drive to find the simplest way to address what is actually a very simple problem. We have achieved this by several metrics: installation of the HBC takes just five to six hours, and the product can easily be retrofitted or installed on new vessels. Once fitted, the product can be maintained during routine drydock visits. In addition, the HBC offers reduced CAPEX compared to existing devices. Thanks to the ease of casting and the lower amount of material required, it costs significantly less to manufacture than current conventional propeller hubs.

The business case for shipowners is compelling. Taking the example of a 250m vessel and a fuel consumption of about 35 tonnes per day, operating for approximately 240 days a year, and assuming a 3% saving return on investment is around five months.

We have already received significant interest from ship owners and propeller manufacturers and are engaging with potential partners to take the concept to market.