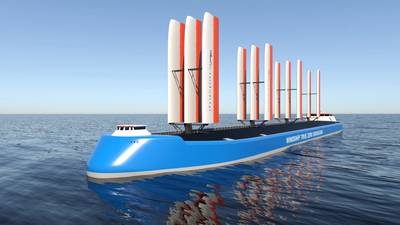

Windship Technology Unveils Emissions-free Ship Design

British company Windship Technology has unveiled a whole-ship solution to tackle CO2 emissions from ships, launching its emissions-free bulk carrier and tanker designs alongside an investment partnership with classification society DNV.

Starting from a clean drawing board, Technical Director Simon Rogers and his design team developed and tested at the Wolfson Unit in Southampton the company’s patented high performance, highly efficient triple-wing rig. The technical team further developed a new diesel electric ship drive system that eliminates CO2, NOX, SOX and particulate matter to True Zero while also incorporating large solar arrays, carbon capture, optimized hull shapes and specialized weather routing software into the overall design package.

The triple-wing rigs produce a driving force several multiples greater than single-masted solutions of the same height currently being promoted in the industry. The 48-meter Windship Technology rig is stowable on deck through a unique stowage solution to aid port navigation and cargo handling. Its composite structure is borne out of technology and design from the wind turbine industry, ensuring reliability and longevity of greater than 25 years.

Professor Philip Wilson, formerly Professor of Ship Dynamics at the Ship Science Department at the University of Southampton, is convinced by Windship Technology’s solution, saying, “The holistic approach demonstrated in this solution whereby wind power, solar power and the reduction of harmful exhaust emissions to effectively zero, are all brought together, means that at last there is a design solution that the International Maritime Organization (IMO) can champion to achieve its requirements for ‘at least’ zero carbon shipping.”

The company also announced a partnership investment with the international registrar and classification society DNV, who will be conducting both an outside-in and inside-out verification to fully assess Windship Technology’s whole-ship design with a view to classifying emission reductions, safety and operability.

Per Marius Berrefjord, Senior Vice President of DNV, said, “We will work closely with the project team in a fully transparent manner as we now initiate the work to establish a simulation model that will help us verify the GHG emission reduction capability of the technology. We are also preparing for a HAZID that shall verify the safety and operability of ships with Windship Technology installed. These activities will be followed by further verification activities as the project moves forward. Windship is supplying information in a fully transparent manner, and DNV will ensure a thorough verification process.”

Speaking about the new cooperation with DNV, Lars Carlsson, Director of Windship Technology, said, “Working with DNV is a major step towards proving true zero emission status. The industry cannot sit back any longer. The clock is ticking and regulation will force a new approach for an industry that is traditionally hesitant to change. Shipping is not fit for purpose in the future. Shipping and oil companies are the only major industries still increasing their emissions and must change and think differently if it is to have any hope of reaching the emissions targets set out in law.”

Against a backdrop of newbuild ship orders down over 50% in 2020, and regulators such as the IMO backed by the United Nations demanding environmental and sustainable reform from the industry, he Windship Technology True Zero Emission solution is being presented as an economical zero-emissions project for oceangoing bulk carriers and oil tankers.

As an investment case, the solution appeals to asset owners looking to secure their investments over the lifespan of a ship’s working life and is attracting significant investor interest in the financial markets, Windship Technology said. The company is now looking to cement commercial partnerships with major ship owners, operators and investors.