WinGD Adds Mitsui E&S Tamano Factory to Engine Building Network

WinGD has concluded an agreement with Mitsui E&S Diesel United (MESDU), part of the Mitsui Engineering & Shipbuilding group, that will see WinGD engines being built at its main Tamano works for the first time.The agreement adds considerable engine building capacity and enables WinGD to meet growing demand in a leading shipbuilding market with a reputation for delivering sophisticated, high-quality vessels.WinGD engines have previously been built only at the company’s Aioi Factory, which was acquired from IHI Group when the Diesel United business was sold to Mitsui E&S earlier this year.

MOL Adopts 'Common Rail Fuel Injection' System

Mitsui O.S.K. Lines, Ltd. announced that its group company, Mitsui O.S.K. Kinkai, Ltd. will use a main engine equipped with the MAN Diesel & Turbo SE (MDT)-developed “common rail fuel injection system” on a newbuilding vessel. Shop test of the main engine was completed on January 29 and the vessel is slated for launching in 2018. After launched, Mitsui O.S.K. Kinkai, MDT and Makita Corporation(President: Yu Makita; headquarters: Takamatsu-shi, Kagawa Prefecture)will continue testing the system with support from MOL while the vessel is in service.

ClassNK CMAXS for Two MOL Ships

ClassNK Consulting Service Co., Ltd. developed next-generation diagnostic monitoring system “ClassNK CMAXS” has been chosen by Mitsui O.S.K. Lines (MOL) for installation on two more ships operated by the company. The system is now installed on a total of six MOL-operated ships. The two ships are installed with CMAXS e-GICSX, a system which monitors electrically controlled main engine supplied by Mitsui Engineering & Shipbuilding Co., Ltd., and CMAXS LC-A for auxiliary engines supplied by DAIHATSU DIESEL MFG. CO, LTD.

MAN Diesel & Turbo, MES Grow Partnership

A new cooperation agreement will intensify existing joint business activities between longstanding partners MAN Diesel & Turbo and Mitsui Engineering & Shipbuilding Co., Ltd. (MES). The agreement was signed by Takao Tanaka, President & CEO of Mitsui Engineering & Shipbuilding, and Dr. Uwe Lauber, CEO of MAN Diesel & Turbo. “Together, we will offer a solution portfolio that is unique in today’s market,” said Dr. Lauber. Expanding upon multiple previous collaborations, the two companies have now agreed to deepen mutual activities within sales…

MAN Debuts New SCR for Two-stroke Engines

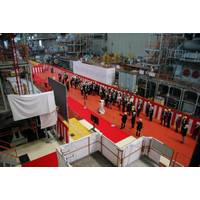

MAN Diesel & Turbo and its licensee Mitsui Engineering & Shipbuilding introduced its new high-pressure selective catalytic reduction (SCR) system, MAN SCR-HP, at an event in Tamano, Japan on April 11. The MAN SCR-HP is available for two-stroke engines of all bore sizes and reduces – through internal catalytic reaction – NOx exhaust emissions to IMO Tier III limits. With specially developed honeycombs and honeycomb materials, as well as an integrated mixing unit, the overall size of the reactor has been drastically reduced compared to typical market designs and its medium-speed counterpart.

First ME-GIE Ethane Engine Unveiled at Mitsui

Mitsui Engineering & Shipbuilding Co., Ltd. (MES) has completed the world’s first ME-GIE ethane-operated two-stroke diesel engine. The engines will be for propulsion of three ethylene carriers, which will also carry ethane as cargo. The Mitsui-MAN B&W 7G50ME-C9.5-GIE is the first engine in a series of three for installation in three LEG (liquefied ethylene gas) carriers of 36,000 m3 for Hartmann Schiffahrt of Germany and Ocean Yield of Norway, being built at Sinopacific Offshore Engineering (SOE) in China.

ClassNK Begins Testing CBM System

ClassNK has commenced verification tests of its next-generation condition-based monitoring (CBM) system ClassNK CMAXS e-GICSX for Mitsui’s MAN B&W engines. The system is being jointly developed by ClassNK, Mitsui Engineering & Shipbuilding Co., Ltd., and MES Technoservice Co., Ltd. and the verification test is being conducted on a MOL-managed vessel with the cooperation of Mitsui O.S.K. Lines. ClassNK CMAXS e-GICSX, based on voyage data, including weather and sea condition and machinery data collected from multiple sensors installed on the engine…

Japan’s First ME-GI Engine Passes Factory Tests

The factory acceptance test (FAT) of the first ME-GI engine in Japan recently took place at the Tamano Works of Mitsui Engineering & Shipbuilding Co., Ltd. (MES), overseen by classification society DNV GL. The engine, developed by MAN Diesel & Turbo, is the first of two 8S70ME-C8.2-GI units for delivery to U.S. shipbuilder VT Halter Marine for installation aboard two 2,400-teu ConRo ships for Crowley Maritime Corporation. VT Halter laid keels for the new vessels in January and August, respectively.

First ME-LGI Engine Test Deemed a Success

MAN Diesel & Turbo licensee Mitsui Engineering & Shipbuilding Co., Ltd. (MES) recently demonstrated the liquid-gas-injection concept in Japan on 17 June, 2015 using the very first ME-LGI engine to ever be commercially produced. The engine, with the type designation 7S50ME-B9.3-LGI, is bound for a vessel currently under construction by Minaminippon Shipbuilding Co., Ltd. for Mitsui O.S.K. Lines, Ltd. Ole Grøne, Senior Vice President – Low Speed Promotion & Sales – MAN Diesel & Turbo described the event as a significant milestone in the development of Diesel technology.

MOL Takes Methanol Fuel Lead

Mitsui O.S.K. Lines, Ltd. has ordered methanol carriers with the world’s first methanol burned dual-fueled low-speed diesel main engine. This engine building has already been completed, and its manufacturer, Mitsui Engineering & Shipbuilding Co., Ltd. has test-operated the unit using methanol fuelin Tamano Works, and confirmed that it metexpected performance. MOL ordered methanol carriers, which will be equipped with this diesel main engine, from Minaminippon Shipbuilding Co., Ltd., (President: Ryutaro Ikebe).

MAN Demonstrates Two-Stroke Methanol Engine Concept

MAN Diesel & Turbo successfully demonstrated its ME-LGI concept engine in front of customers and partners at its Diesel Research Center in Copenhagen on March 17th, the company announced today. “A number of years ago we identified the need to develop an engine that could run on more environmentally-friendly, competitively-priced fuels as an alternative to MDO/MGO," said Vice President and Head of R&D, Søren H. Jensen. "We believe the ability of the ME-LGI engine to run on sulfur-free fuels offers great potential. Methanol carriers have already operated at sea for many years.

MES Delivers Bulk Carrier to Lepta Shipping

Mitsui Engineering & Shipbuilding Co., Ltd. (MES) completed and delivered a 56,000 dwt type bulk carrier M.V. Alam Makmur (MES Hull No. 1866) at its Chiba Works on March 16, 2015 to Lepta Shipping Co., Ltd., Liberia. This is the eighth ship of MES’ neo56BC, the new generation eco-ship. According to the builder, this keeps the usability and reliability of Mitsui 56 which has seen more than 160 units delivered by MES. The vessel has four cranes and five cargo holds and is designed for loading various cargos like coal, ore, grain, as well as lengthy/heavy cargo such as steel pipe and hot coil.

ClassNK, Makita Expand Engine Monitoring

ClassNK and Makita have agreed to bring the condition-based engine monitoring system ClassNK CMAXS e-GICSX to Mitsui-Makita MAN B&W main engines. The system assists in the early detection of abnormalities in electrically controlled diesel engines and is being developed in collaboration with Mitsui Engineering & Shipbuilding. Its development comes in response to the rise in the number of vessels being equipped with fuel-efficient electronically controlled diesel engines that allow large amounts of sensor data to be obtained.

MES Delivers "Eco Friendly" Bulk Carrier

M.V. Mitsui Engineering & Shipbuilding Co., Ltd. (MES) completed and delivered a 56,000 dwt type bulk carrier M.V. “HANJIN CHIBA” (MES Hull No. 1829) at its Chiba Works on 19th November, 2014 to VENUS OCEAN NAVIGATION S.A., Panama. This is the 7th ship of our “neo56BC”, the new generation eco-ship. This keeps the superior usability and reliability of “Mitsui 56” which is highly appreciated in the market and more than 160 units have been delivered by MES. The electronic controlled engine and optimized shape make the superior propulsive efficiency and fuel oil consumption.

Fuel-saving Modifications for Containerships’ Engines

Mitsui Engineering & Shipbuilding Co., Ltd., and 100% owned subsidiary MES Technoservice Co., Ltd., have received an order from a Taiwan shipowner for fuel-efficiency modifications to the main engine (Mitsui-MAN B&W 12K98MC/M6) of three large type container vessels. In recent years the rising costs of fuel oil together with the need to reduce the environmental impact of shipping vessels have sharply increased the practice of slow steaming especially for large container vessels whose annual fuel oil costs can run into the billions of Yen.

Joint Project Studies Condition-based Engine Monitoring

Classification society ClassNK announced that it will participate in a joint project together with Mitsui Engineering & Shipbuilding Co., Ltd. and MES Technoservice Co., Ltd. ClassNK will support research into the development of condition-based engine monitoring systems for the Mitsui MAN B&W engine. The developed systems will assist in the early detection of abnormalities in electronically-controlled diesel engines in ships. In recent years, vessels are increasingly being equipped with more fuel-efficient electronically-controlled diesel engines…

MAN ME-LGI Engines Contract Confirmed

MAN Diesel & Turbo says that Vancouver-based Waterfront Shipping has confirmed its Methanol Carrier Project for a series of 50,000-dwt methanol carriers, each powered by an MAN B&W ME-LGI main engine running on methanol. The confirmation stems from a Letter of Intent MAN Diesel & Turbo and Waterfront signed earlier. MAN Diesel & Turbo officially designates the ME-LGI engine as ME-B9.3-LGI. In collaboration with leading shipping lines, Waterfront reports that it is behind the 2+1 × 6G50ME-LGI engines ordered by Westfal-Larsen, the 2+1 × 7S50ME-B9.3-LGI by Mitsui O.S.K.

Fukushima Experimental Offshore Floating Wind Farm Project Progresses

A consortium made up of Marubeni (project integrator), the University of Tokyo (technical advisor), Mitsubishi, Mitsubishi Heavy Industries, Japan Marine United, Mitsui Engineering & Shipbuilding, Nippon Steel & Sumitomo Metal Corporation, Hitachi, Furukawa Electric, Shimizu, and Mizuho Information & Research has been participating in an experimental offshore floating wind farm project sponsored by the Ministry of Economy, Trade and Industry since March 2012. At present, the construction of the three-column semi-sub as part of the second phase has been successfully completed.