Interview: Dirk Balthasar, President, Thermamax

To start, can you give an overview of the Thermamax offering to the maritime industry?

Thermamax is a specialist in the design and manufacture of thermal and acoustic insulation solutions for diesel engines, spark ignited engines, exhaust aftertreatment systems and electric storage systems. Our markets include automotive, on- and off-highway sectors, power sports vehicles, stationary power generation, ships, and oil platforms, both on land and at sea. For the marine industry, Thermamax is a solution provider for SOLAS-compliant insulation solutions for engine rooms. We supply highly effective insulation claddings for most of the leading engine and turbocharger OEMs. In addition, Thermamax is able to design, manufacture and install SOLAS- compliant retrofitting insulations also for engines that are already in service for a longer period of time and that eventually do not meet latest safety standards. This is relevant for cruise ships and offshore vessels, but really for any commercial ship.

Looking at your business globally, what percentage is to the maritime and offshore segment?

About 20% in 2018.

When you look at your range of products to the maritime sector, what is the top driver?

The number one driver certainly is safety. According to IMO SOLAS the surface temperature of modern marine engines must not exceed 200°C. In addition, engine builders are striving for better fuel efficiency, mainly by increasing the engine`s power density what typically leads to higher exhaust gas temperatures. Due to higher charge air pressures even the area of the compressor outlet of the turbocharger becomes a concern in terms of surface temperatures. Consequently, every new engine has to be equipped with a highly efficient insulation system. But as already mentioned, higher levels of safety are also important for older engines that do not meet latest SOLAS requirement. For these engines, Thermamax is able to design custom made retrofit solutions and to install them on board.

As you know, emissions reduction is the focus in maritime today. Do Thermamax products have a role in helping vessel owners achieve reduced emissions?

Thermamax insulation systems are often used for exhaust after treatment systems. Let it be the pipes between the turbocharger outlet and the SCR, or the SCR itself. Our insulations keep the heat in the system and temperatures at a level that is required to ensure proper catalytic reaction in the SCR.

We understand that Thermamax is also investing in product development to support increased electrification and batteries on ships.

Recently Thermamax developed housings for battery modules to support electrification, beside others, for marine application. Also, on board ships electrification is becoming more and more important. Thermamax battery housings can be used for on-board energy storage systems, replacing conventional Diesel generators. Our battery housings ensure effective fire protection and extend the battery range by balanced thermal management.

Geographically, by vessel type – or by both – where do you see opportunity in the maritime sector today?

Safety and efficiency is of global importance, particularly a major concern in the cruise and oil & gas sector.

The Tmax-Retrofit

In the engine room temperatures are highest and reliable fire prevention is vital. As 3D details are often not available for older engines, retrofitting with SOLAS-compliant high-performance insulation systems has only been possible to a limited extent until now.

With Tmax-Retrofit, older marine engines can now also be upgraded with high-temperature insulation systems which exceed SOLAS guidelines. The all-in-one package provides all services – from the preparation of the engine’s 3D profile to the thermography of the developed and installed insulation system – all from one source.

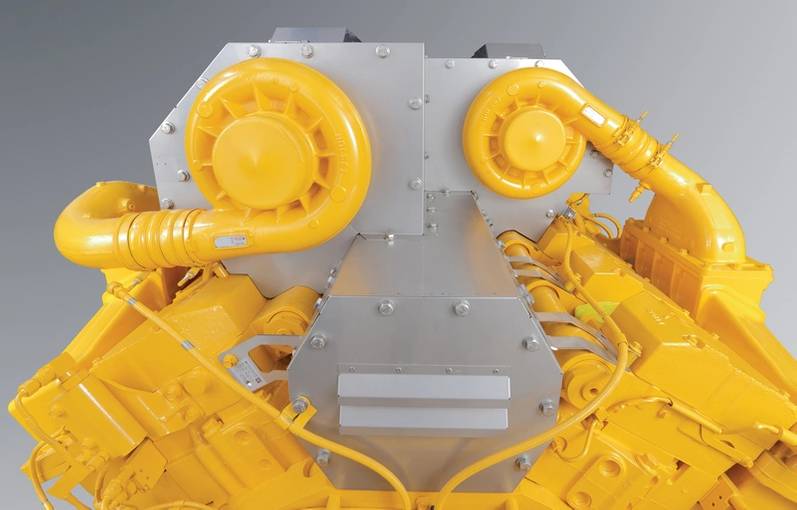

Tmax-Retrofit. Image: Thermamax1. A 3D-Scan of the engine to ensure the best fit of the exhaust gas and turbocharger cladding. Results of the scan are used as the basis for preparing digital 3D models.

Tmax-Retrofit. Image: Thermamax1. A 3D-Scan of the engine to ensure the best fit of the exhaust gas and turbocharger cladding. Results of the scan are used as the basis for preparing digital 3D models.

2. Reverse Engineering: Based on the scanned 3D profile, Thermamax develops a CAD model of the engine. For this it first generates a polygon network in STL format from the available data. This is converted into standard geometries and free-form surfaces. From these attributed surface models and own on-site photos, we can then create a CAD model in the STEP or IGES format.

3. Design and Simulation: Now starts the classic design process. On the basis of a 0D/1D thermal calculation Thermamax defines material and thickness of the insulation. The detailled constrution is made in Creo, a specialized software. The result is a durable exhaust gas/turbocharger cladding which reliably lowers the maximum surface temperature below 220°C and even below 100 °C, depending on requirements.

4. Manufacture: First, Thermamax produces a prototype. In its own test lab, it performs various tests on all materials and components to ensure high quality in practical applications.

The individual Tmax-Insulation Cladding is now ready to use and can be installed.

5. Installation: Thermamax installs the exhaust gas/turbocharger cladding – first the prototype – on your engine.

6. Thermography: To ensure that the new insulation system performs as required, Thermamax performs a thermography test.