GE Gas Turbines to Power US Navy's DDG Destroyers

GE’s engineering team also collaborates with Bath Iron Works on the LM2500 module modernization program. Through this initiative, GE designed a composite enclosure that has a 50% reduction in wall weight and several crew safety features. Introduction of this lightweight composite enclosure is anticipated in the next year.

In 2013, the U.S. Navy awarded Bath Iron Works DDG 126 under the contract that was part of a multi-year competition for DDG 51-class destroyers; DDG 127 was approved by Congress under separate legislation. The U.S. Navy has named DDG 126 the Louis H. Wilson, Jr., after the 26th Commandant of the U.S. Marine Corps, who was a World War II recipient of the Medal of Honor for his actions during the Battle of Guam. Currently there are four DDG 51 destroyers in production at Bath Iron Works: Thomas Hudner (DDG 116), Daniel Inouye (DDG 118), Carl M. Levin (DDG 120) and John Basilone (DDG 122).

GE has already delivered over 750 gas turbines to the U.S. Navy to power frigates, destroyers, cruisers and amphibious ships. In addition, the company has nine depot service centers worldwide that provide full overhaul capability for the LM2500, avoiding the need to send gas turbines overseas for shop maintenance. Thus, GE is well positioned to support the world’s naval propulsion needs via its six propulsion gas turbines that range in power from 4.5 to 52 megawatts. This flexibility enables architects to design ships according to specific mission profiles and cost objectives.

Fleet commonality of a single gas turbine also affords the U.S. Navy a support pool of standardized spare parts, a common gas turbine infrastructure and training program for these fleets, and the flexibility to move propulsion crews across ship platforms with no incremental training.

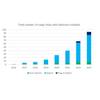

The LM2500 is the most reliable gas turbine in the market with over 15 million hours in marine applications as well as another 70 plus million hours in industrial applications. These gas turbines reliably operate for the U.S. Navy and 34 other navies the world over in some of the most arduous conditions.