EPA Tier 4: Difficult and Contentious, 12 Years and Counting

When it comes to complying with EPA’s Tier 4 emissions regulations, there’s no shortage of creativity emerging from America’s maritime engineering firms. Companies such as Hug Engineering are offering flexible, customized aftertreatment-based control systems that can assemble almost in modular like fashion. Other companies, such as ABB Group, offer battery-hybrid power sources to complement combustion power and avoid threshold diesel emissions. Engine manufacturers, such as Cummins, are working with aftertreatment suppliers to ensure operational harmony between power plant and pollution controls. Scania AB is demonstrating new successes by approaching power from a systems standpoint, taking a close look at a vessel’s actual power demands and how and when that power needs to be delivered.

As vessel owners know, this is not easy stuff – in any way. Tier 4 systems are complex and expensive, to purchase and operate. They are big, frequently requiring customized, specific analyses for placement within a vessel; a challenge and difficulty that EPA refers to as “packaging,” literally working to fit the hardware and related components inside a hull. Tier 4 demands are rigorous: emissions from 25 Tier 4 engines are supposed to be equivalent to just one Tier 1 engine. The vessel, its engine and the aftertreatment need to function as a single system for optimal performance, reliability, cost and emissions reduction.

From discussions with experts in the Tier 4 field, some of the Tier 4 installation technical challenges are being met. Progress is slow but new vessels, at least, are being designed to incorporate Tier 4 engines and the aftertreatment systems which, of course, require as much room as the engines to which each unit must be linked.

(Image: Hug Engineering)

(Image: Hug Engineering)

Importantly, though, these advances must spread out across a very fractured landscape. Progress with one vessel or application doesn’t mean success elsewhere. Each different class of vessel requires a different approach and analysis to Tier 4 implementation, lobster boats are not the same as ferries which are not the same as pilot boats. It’s not an exaggeration to write that every vessel – not just every vessel class – demands its own analysis.

Tier 4, of course, doesn’t apply just to new vessels. A vessel owner seeking to repower an older vessel confronts the same long list of questions and trade-offs. He or she may decide it’s easier just to avoid the whole set of issues and instead of buying one Tier 4 engine at 800 HP (the 800 HP Tier 4 threshold, also 600 kW) he or she may purchase two smaller engines instead. And increasingly, hybrid applications, using electric and diesel power generation are drawing operators’ attention. Hybrid systems double-up, when needed, to deliver maximum power under load, and maximum load is usually just a fraction of a vessel’s operating time.

To make matters more complicated, the Tier 4 market and business milieu remains shaky. Tier 4 decisions sit within an unsettled regulatory environment – even though EPA’s regs were finalized in 2008 and Tier 4 phase in was supposed to have concluded by 2017. This uncertainty impacts decisions across the board – at shipyards, among engine manufacturers and vessel owners.

© Wimbledon / Adobe Stock

© Wimbledon / Adobe Stock

Last September, EPA proposed to delay Tier 4 implementation for certain types of vessels – high powered vessels such as lobster boats. In response, comments came in from across the industry imploring EPA to expand the scope of that delay – to include a broader range of vessels, from workboats to tour boats. EPA’s public comment period ended in October. However, behind the scenes, EPA has maintained an active and pointed discussion with industry reps, asking for their perspective on the charges and countercharges within the Tier 4 debate. The many issues with Tier 4 compliance remain hotly contentious.

EPA was counting on vessel design changes and technological advancements to be market ready by 2017. EPA allowed that development time to resolve the “packaging” issues (EPA’s term) that stymied a quicker phase-in in 2008; EPA knew that application and installation of Tier 4 aftertreatment was still some years off. Ten years later, though, the “packaging” problems remained. “(EPA’s) decade-old assumption of how the market would respond has proven to be incorrect,” is the way Robert J. Lawler, Jr., President of the Passenger Vessel Association summed up the Tier 4 state of affairs in comments to EPA.

EPA is targeting summer 2020 to issue a final action on its proposal to delay.

Dana Brewster (Photo: Hug Engineering)

Dana Brewster (Photo: Hug Engineering)

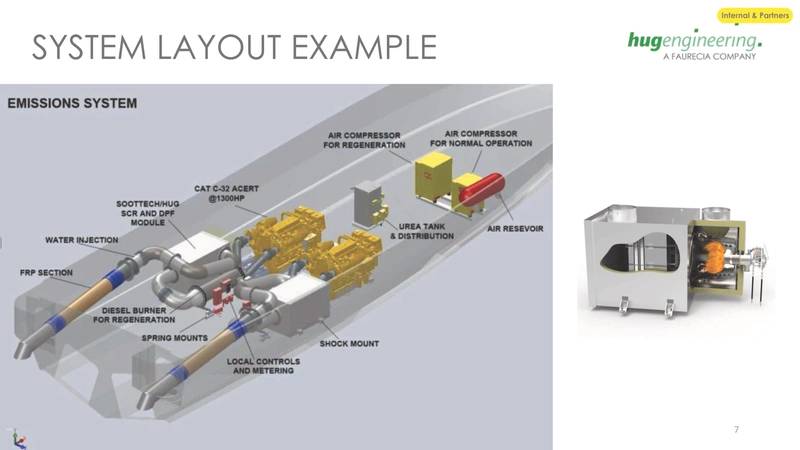

Hug Engineering’s approach to Tier 4 compliance illustrates how engineers are seeking maximum flexibility regarding materials and space. This kind of advance is important for vessel owners seeking to repower. You may not have been able to fit a Tier 4 system in your vessel five years ago. Today, that same space might work for installing an aftertreatment system to your existing engine.

HUG Engineering offers a retrofit aftertreatment selective catalytic reduction (SCR) to reduce NOx emissions to Tier 4 standards. A diesel particulate filter (DPF) can be added to the SCR system to also reduce particulate matter (PM). HUG’s Nauticlean and Clean4Marine systems are adaptable with various engines; in fact, HUG has certifications for IMO III today and additional engines currently in the certification process. HUG partners with some of the marine diesel engine OEM’s on a global scale. Another Tier 4 path to explore is a “Best Available Technology” (BAT) option. When a Tier 4 engine is unavailable for repower applications, air quality agencies in some cases may consider the BAT.

Dana Brewster is Hug’s Regional Sales Manager, Mobile Applications (Marine/Rail). He said that HUG’s engineers take what he calls a “Lego approach” to aftertreatment installation, i.e., to fit it into just about whatever space is available. Brewster said that Tier 4 control schemes can, increasingly, be installed in various configurations. If there is more vertical space available, the hardware gets stacked. In a narrow but more lengthy space, the system will stretch out. But if you need an engine in excess of 800 HP, the odds are better now that Tier 4 can work. Again, though, there are no across the board answers with Tier 4.

Boyer Towing recently repowered its 1997-built tug Gretchen H three new Cummins QSK19 Tier 3 compliant engines rated for 750 HP each at 1,800 RPM. (Photo: Cummins)

Boyer Towing recently repowered its 1997-built tug Gretchen H three new Cummins QSK19 Tier 3 compliant engines rated for 750 HP each at 1,800 RPM. (Photo: Cummins)

Eddie Brown, Segment Leader, Commercial Marine at Cummins Engines, said his team is “working closely with naval architects and customers on power solutions that meet Tier 4 emission levels and enable vessels to complete their missions.” Brown said that “overall, the impact of cleaner emissions systems on vessels does vary.” Some vessels can accommodate new aftertreatment systems without significant vessel redesign. However, in higher speed and/or weight-sensitive applications, Brown said “there may be a need to redesign or reconfigure the boats and their engine rooms.” Cummins works closely with customers on these kinds of projects.

Brown said that alternative power solutions are on the horizon, from diesel-electric hybrids to hydrogen fuel cells. “Customers want to optimize their vessels with the best power packages to meet regulatory rules and still provide the most efficient engine performance.”

Hybridization is a big focus for ABB and its marine generator products. ABB’s low voltage (LV) standard marine generators are designed for fully electric vessels and for marine diesel gen-sets in main, auxiliary or emergency power generation. They cover the power range 14-2,600 kVA in frame sizes 180-450 with typical voltages of 380-480 V. This equipment is well-tested in marine applications, currently working in over 1,300 ships.

Dave Lee , ABB’s Senior Account Manager, New Build, describes a hybrid evaluation as part of a “different thought pattern” regarding vessel power. He notes that in a workboat, for example, full engine power is rarely used. ABB installs smaller generators to complement the diesel engine. “We offer an optimal power range and battery and fuel cell technology,” Lee said. This approach can avoid the need for a second diesel engine. It utilizes horsepower most effectively, depending on the task at hand.

David Lee (Photo: ABB)

David Lee (Photo: ABB)

The notion of strategic power is an important one for Scania, which is not offering engines over 800 HP in the U.S. That high-power market is too limited. As designers evaluate future power demands, Alberto Alcalá, U.S. marine sales manager for Scania, predicts additional progress on vessels themselves: shaped for speed and energy efficiency.

He too expects increasing hybridization, writing that “hybridization can fill in the gap between tier 3 and the need for a larger engine with the complexities of tier 4.” In 2012, Scania outfitted the Hornblower Hybrid in San Francisco with a Tier 2 / electric mix. That ship was recently upgraded to a Tier 3 / electric mix in order to meet California’s tougher air quality goals.

Alberto Alcalá (Photo: Scania)

Alberto Alcalá (Photo: Scania)

Alcalá placed hybridization at the top of the list regarding future disruptive technologies. Scania works with ABB (and others) on projects that demonstrate how a mix of electric-diesel generation can replace larger engine sets.

Scania engineers have demonstrated that three smaller engines can replace 3-4 engines in a traditional 2,000 HP tug, at tier 3 levels. New gensets can provide up to 2,400 HP in what was once a 2,000 HP vessel. The vessels use power as needed – idling or shutting down in low-load situations, using dramatically less fuel, then drawing maximum power only when needed, again, usually a relatively small portion of a vessel’s operating hours.

Stay tuned for EPA’s decision this summer.

Hot Enough to Boil Water… Lobster boats were highlighted by EPA. Lobster boats need specific compartments for live lobsters. But the “packaging” required for larger engines (above 600 kW) placed the engines – and heat – too close to the lobsters. Then, add SCR heat and the outcome was not good – the lobsters were getting cooked, or close to it. This example may be a bit singular, but the issue of heat dispersal is a critical safety issue. R.W. Fernstrum & Company has been designing and building heat dispersal systems for 70 years. We asked Fernstrum: what are your customers asking about regarding repowering and Tier 3 vs Tier 4 options? Vessel owners could, for example, install three Tier 3 engines instead of two Tier 4 engines, thereby avoiding SCR systems altogether. Plus, this saves space, a critical concern within overall vessel design and performance – whether for speed or cargo. “Our company’s goal is to reconfigure existing technology in even more efficient ways,” explained spokesperson Rachel Fernstrum. “Our systems allow us to reject more heat in a given area of the vessel.” Ferstrum added that this approach retains a familiar technology, avoiding a new, and complex, SCR learning curve. “We can retrofit keel coolers in a vessel to replace an existing cooling system that may not be working as expected,” Fernstrum said. In addition, the company can also “leverage” an existing cooling system, as long as it is a closed-circuit system. This “leveraging” can reduce the additional cooling requirements associated with certain applications. Sometimes, with a repower, the keel coolers from an original installation may be able to be used as part of the new cooling system. The point is: if you’re facing these difficult decisions, check all options. |