Energy Storage Systems Continue to Expand in North American Maritime Markets

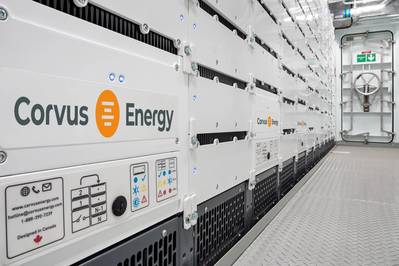

Corvus Orca Energy, the world’s most widely deployed maritime ESS, is versatile for a wide range of applications and scalable from 80-10,000 kWh. (Photo: Corvus Energy)

North America is increasingly adopting energy storage systems (ESS) to use in combination with combustion engines or as the sole energy carrier in fully electric-powered systems.

We clearly see a transition from ‘consideration’ to ‘execution’ of hybrid and all-electric maritime projects. Stakeholders want to explore how to make vessels more energy efficient and less polluting. Corvus Energy has deployed over half of the ESSs aboard vessels globally, totaling over 300 megawatt hours (MWh).

In North America, Corvus has deployed 24 MWh of energy storage capacity, and there are 13 vessels under U.S. Coast Guard jurisdiction and nine with Canadian flag either commissioned or under construction.

Trends in ESS technology

Just a few years ago, battery size was the main consideration. Corvus would analyze a vessel’s load profile and size the battery system to exactly meet anticipated loads. However, as battery costs go down, other cost factors in the complete electrical solution rise to prominence. Now we see a more relaxed approach to battery sizing, as owners discover operational flexibility in higher battery capacity.

Different types of vessels have widely varying energy storage and charge/discharge requirements. As such, Corvus has developed a portfolio of energy storage solutions that take advantage of the strengths of selected battery cell technology to offer differing performance characteristics.

The following describes the ESSs we deploy on board vessels, their distinguishing features, and their most suitable applications:

Orca — Robust flexibility with fast-charging capability

Corvus Orca is our most widely selected battery system worldwide due to its scalability, fast charge/discharge capabilities, and ease of installation. It uses a Li-NMC cell and patented technology to optimize safety and performance.

It was Orca that broke through the cost/benefit intersection, raised the bar for maritime battery safety standards, and started rapid adoption in Nordic countries. Corvus Orca is now deployed on more than 200 vessels worldwide and has surpassed 2 million operating hours. It has proven to suit many vessel types and operating profiles, including offshore support vessels and shuttle tankers, car and passenger ferries, coastal cargo vessels, workboats, tugboats and fishing/fish farm vessels.

Dolphin — The highest energy density for weight-sensitive applications

For weight-sensitive vessels, such as fast-ferries and high-speed workboats, Corvus Dolphin may be a better choice. Its very high energy density can allow for more batteries on board, which may reduce how often they need to be charged. One of the trade-offs is a slightly reduced charging speed compare to Orca. As weight-sensitive fleets are electrified, operators may need to reconsider route scheduling. For example, a couple minutes more at the dock might represent significant reduction in shore power requirements.

Corvus Dolphin is available in power- and energy-optimized versions. Like Orca, both Dolphin Energy and Dolphin Power have Li-NMC cells and are modular and scalable for ease of installation.

The Corvus Dolphin ESS, with the industry’s highest energy density, is ideal for high-speed vessels and other weight-sensitive applications. (Photo: Corvus Energy)

The Corvus Dolphin ESS, with the industry’s highest energy density, is ideal for high-speed vessels and other weight-sensitive applications. (Photo: Corvus Energy)

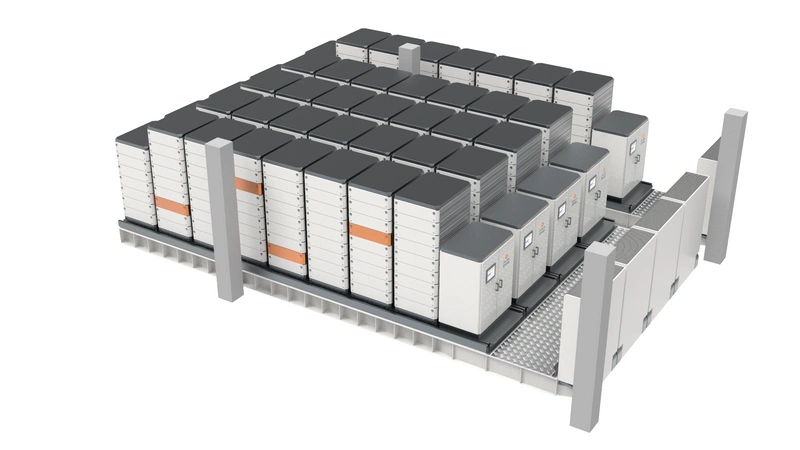

Blue Whale — Highest energy capacity and battery room volumetric energy density

Corvus developed the Blue Whale ESS with big ships—ferries, cruise ships and cargo vessels—in mind from day one. Blue Whale has the industry’s highest volumetric density, as it is designed to very efficiently be stacked in large battery rooms with service access from the top.

The cell technology is LiFePO4 (also called LFP), which provides excellent depth of discharge. This cell characteristic is vital when large ships aim for longer durations with zero emissions, for example, port stays and voyages in fjords or other waterways within sensitive environments or populated areas.

ESS — a partner in power

In an all-electric vessel, the ESS supplies power to the vessel’s electrical components, including propulsion motors. It’s that simple.

For a hybrid vessel, the batteries are “a partner in power” with diesel or gas engines. A properly integrated battery system optimizes the power plant at all times. It absorbs load variations and provides power instantly as needed, which often means avoiding starting backup engines. The batteries can also store regenerative power from cranes, winches and similar equipment. Overall fuel savings for vessels with complex load profiles can be in the 20%-30% range.

Corvus ESSs are built upon an open interface platform that can connect with any electrical system, providing vessel owners freedom of choice. Worldwide, we have interfaced our batteries to more than 25 electrical integrators. As we expand our portfolio of ESSs, vessel owners and electrical integrators will be able to select the most suitable battery system without major changes to their Power Management Systems.

Sizing of systems and lifecycle expectations

Designing, building, and operating a hybrid vessel requires different thinking, and Corvus supports the development of operational philosophies with batteries as an essential part of the power plant design. Once operating parameters are determined, Corvus can determine required energy capacity and lifecycle expectation.

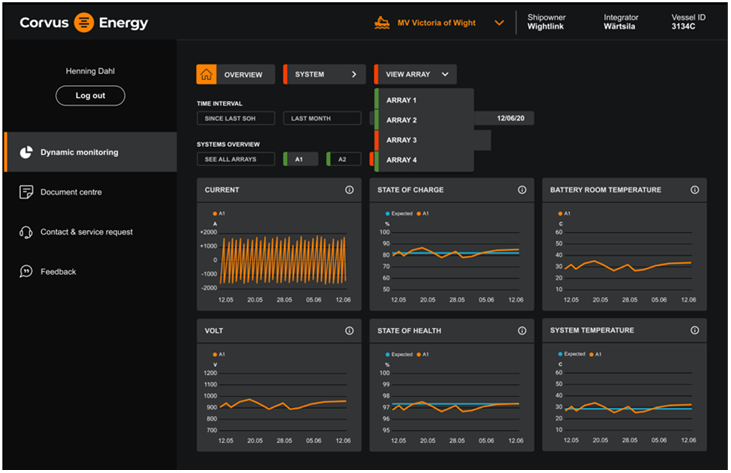

The industry has mostly settled on a 10-year lifecycle, although that can be adjusted primarily with battery size selection. Corvus offers shipowners real-time battery monitoring, accessible through a cloud-based portal, that tracks actual battery usage and state-of-health to optimize the battery’s performance throughout its lifecycle.

The Corvus customer portal provides shipowners a real-time view of battery state-of-health throughout its lifecycle to optimize performance. (Image: Corvus Energy)

The Corvus customer portal provides shipowners a real-time view of battery state-of-health throughout its lifecycle to optimize performance. (Image: Corvus Energy)

Container-based solutions, driven by industry stakeholders

Another trend is to deliver systems in enclosures based on standard container dimensions. Traditionally used in retrofit projects, we see an increasing number of new constructions leaning toward containerized solutions. The packaging allows owners and charterers to look at energy systems as building blocks. In the future, vessels may be capable of adjusting the number of containers on board to change its hybrid profile without intrusive rebuilds.

We also see potential to combine containerized batteries with clean energy carriers, such as hydrogen, to store excess energy generated in fuel cells and offload the vessel’s peak demands.

New technology is welcomed

In recent years, we have witnessed a groundswell of acceptance of battery technology as a viable and practical solution to fleet electrification. There is no longer any doubt that the future is electric, but we still have a long way to go on our way to zero emissions.

Working together across the industry will be a key to success. Corvus keeps future trends in mind when designing our products, and we always strive to make them as adaptable as possible to existing and emerging standards. We look forward to continued discussions and collaboration within the North American maritime industry, its shipowners, vendors, class societies, trade organizations and government to drive innovation further.

Corvus Blue Whale, a compact ESS to optimize battery rooms in large-scale systems (Image: Corvus Energy)

Corvus Blue Whale, a compact ESS to optimize battery rooms in large-scale systems (Image: Corvus Energy)