Bureau Veritas Certifies 3D Printed Propeller

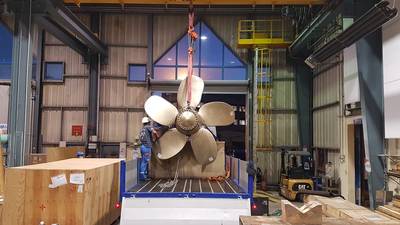

Bureau Veritas (BV) said it has certified a new-generation 3D printed propeller manufactured by Naval Group for a Tripartite-class minehunter vessel.

“This technology is promising and opens the room for further, more complex, innovations in additive manufacturing,” Laurent Leblanc, Senior Vice President Technical & Operations at Bureau Veritas Marine & Offshore.

With its 2.5-meter span supported by five 200-kg blades, the propeller is said to be the largest metal 3D-printed propeller ever manufactured. BV also claims it to be the first one made using additive manufacturing technology to equip a military ship in operation.

"Obtaining military naval quality requires rigorous development," BV said. "Bureau Veritas has been involved at every step of the manufacturing and testing process. Building on our technical expertise and innovation capabilities in 3D printing technology for the maritime industry, we worked closely with Naval Group throughout the process to define the qualification plan for the process, define the production testing and inspection plan for the 3D printed parts, witness manufacturing steps and testing and verify the quality records and test reports."

Emmanuel Chol, Director of the Naval Group Nantes-Indret site, said, "Including Bureau Veritas from the very beginning was vital for us to reach our goal of bringing the WAAM (Wire Arc Additive Manufacturing) process from its research & development stage to actionable industrial standards."