Wabtec's Power Play

With shipowners pressed to upgrade machinery to meet strict new emission targets, there’s much confusion with chatter surrounding ‘decarbonization’ and ‘future fuels’, solutions that don’t exist today – and may not exist in mass for another generation – cluttering the conversation. Enter Wabtec, formerly GE Transportation, which today offers a Tier 4 compliant engine with no need for urea. Is it the cheapest propulsion solution on the market? No. But the Pennsylvania-based engine builder mounts a compelling case for its 250MDC diesel engine based on performance, fuel efficiency and lifecycle costs.

Offering a power solution that is proven across industries, and compliant with the highest environmental regulation with the bonus of accomplishing this without the extra cost and hassle of a urea treatment system would seemingly make Patrick Webb’s job easy. But seemingly that’s not the case.

“There’s confusion around EPA Tier 4 emission requirements and decarbonization,” said Webb, a maritime industry veteran who serves as Wabtec’s Global Senior Sales Director, Marine, Stationary and Drill Group. “Where the EPA is focused on lowering pollutants that cause serious health issues, the media seems to be focused on lowering carbon. Also, there is very little real availability of different renewable (fuel sources) across the US and around the world.”

Webb and his team at Pennsylvania-based Wabtec are eager to share the story of the company’s medium speed, EPA Tier 4 compliant engine, which today has more than 100 engines installed in vessels, representing an aggregate of more than 1,000,000 cumulative hours running. “Wabtec has an awesome, proven solution that allows vessels to operate at the extreme EPA Tier 4 emission level, without any need for urea, but many customers are still fighting to try and find ways to avoid this emission standard,” citing recent examples where operators – commercial and government – choose to install a larger number of smaller horsepower engines to effectively circumvent Tier 4 emission standards. “There is a lot of talk about cleaner emissions, but behind the scenes, there has also been efforts to avoid cleaner emission and the perceived cost and hassles of this next level of emission control.”

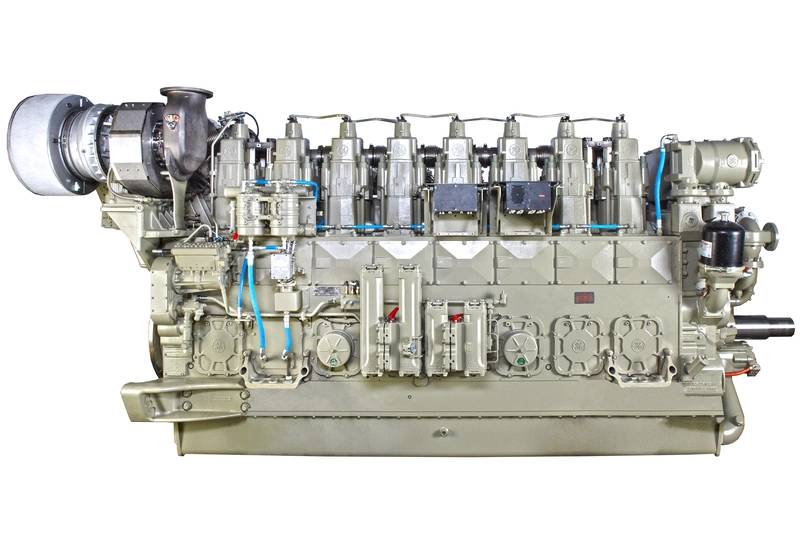

Despite the challenges, Wabtec has enjoyed measured success in recent years. “Wabtec Marine Diesel has transitioned from a near 0% market share in the U.S. before EPA Tier 4 rules came out,” said Webb. “Six years later, the Wabtec Tier 4 Marine Diesel has captured nearly 50% of these new engine sales in the 1.7MW to 4.5MW powerband. This success is in large part associated with the fact that Wabtec Marine Diesel is the only engine of its type that can achieve the strictest emission standards with no need for urea.” 8L250MDC. Image courtesy Wabtec

8L250MDC. Image courtesy Wabtec

The engine

The L250/V250MDC diesel engines from Wabtec meet U.S. EPA Tier 4 and IMO Tier III emission standards with advanced exhaust gas circulation (EGR) and without the need to use urea. The omission of urea is a particularly important designation. “The Wabtec advantage with its Tier 4 engine starts with the fact that there is no urea needed, meaning that you don’t have to allocate the space for the extra equipment needed for the tanks and storage of urea; and also, from the cost of ownership,” said Matthew Hart, Platform Leader, Marine & Stationary Power Systems, Wabtec. “The Tier 4 250MDC product is EGR-based, with increased robustness designed into the power assembly, two-stage turbocharging and high-pressure fuel injection. It’s about fuel efficiency too, and its impact on the total cost of ownership.” While the Wabtec team is quick to admit that the 250MDC is not the cheapest engine on the market, according to Hart. When all is taken into consideration there is a payback period of approximately 18 to 24-months.

In addition to the hardware, Wabtec has built into the engine a sensor array that is common for its rail customers, and is now starting to make headway in the marine industry. “These are digital engines,” said Hart. “That comes with increased capability for onboard diagnostics on the Tier 4 engine, there’s improved diagnostics because of all the sensors that are related to Tier 4 emissions control.

According to Hart, the rail industry is more advanced in the collection and use of data, with modems on the locomotives that continuously stream data. “We have a global performance optimization center that collects that data and sends out recommended actions. It’s a little bit of a different service structure in the locomotive space, but we’re looking at how we can expand that on the marine side.”

He noted that data connection on the marine side is the tough part. “Vessels operate everywhere, and a lot of times without connectivity, so there’s a more manual step of making the data accessible and then processing it.”

Ultimately, he and the Wabtec team hope to help the maritime industry transition from calendar-based to condition-based monitoring, “so it’s not just the diagnostics of when something fails, but we move ahead to predictive maintenance, saying ‘Hey, you should change this part, change this filter because we’re seeing this trend on the engine.”

While some companies may be hesitant to share data, Peter Twichell, Director, Project Management, Marine Customer Support, said that increased data share and analysis can help support owners to increase their uptime. “Uptime is critical in the maritime industry, and in our experience, they’ve been very supportive,” said Twichell. “We really don’t have much pushback from the client when we ask for log files if we explain it in regards to troubleshooting or predictive management, particularly if we can identify and fix an issue faster.”

“As long as the engines we operate are modern and well maintained and our hull forms are fair, there isn’t a more efficient means of transportation...” – Christian Reinauer, Reinauer Transportation. Image courtesy Reinauer Transportation

“As long as the engines we operate are modern and well maintained and our hull forms are fair, there isn’t a more efficient means of transportation...” – Christian Reinauer, Reinauer Transportation. Image courtesy Reinauer Transportation

Put to the (Reinauer) test

Christian Reinauer, Reinauer Transportation, perhaps better than anyone, can deliver insight on the long-term value of the Wabtec Tier 4 solution. Reinauer operates a fleet of ATBs and tugs out of NYC, with a total of 24 barges and 23 Tugs. Of that fleet, Reinauer has four Senesco Marine-built tugs of three classes using the Wabtec 250 series engines: Bert Reinauer with 2x 12V250; and the Josephine, Kristy Ann and Janice Ann Reinauer, all with 2x 6L250.

In discussing the rationale behind the selection of Wabtec, Reinauer said, “We had built a fleet of vessels using MTU 16V4000 series, and with the Tier 4 requirement MTU did not have an approved solution to offer.”

So Reinauer started looking at the full range of engine offerings from all manufacturers, it settled on the Wabtec design with the omission of urea as a major selling point. “We felt the EGR design was a good choice since it had been around for awhile,” said Reinauer. “The DEF solutions required considerable exhaust system design, which we really didn’t have room for, as well as approximately 8% of the vessels capacity dedicated to the storage of DEF. DEF fluid is somewhat caustic to metals so the tanks would have to be specially coated to handle it, which down the road would be a maintenance headache.”

Reinauer also said that maintenance needs to be performed on the catalysts, “which again made designing in for ease of maintenance a headache and additional cost to overhaul. The (Wabtec) engines were more expensive up front and more difficult to install but at the end of the day we have a better economy and crew comfort for the life of the vessel.”

Even in the best of conditions, there are learning curves and technical hiccups when integrating new machinery across a fleet, and Reinauer was not exempt. “We have only had a few issues of any real consequence: a few EGR coolers and valves which (our) engineers can swap themselves; a water pump and a seawater pump; a few engine power supplies and sensors. Otherwise, according to Reinauer, parts have been installed based on scheduled maintenance.

Reinauer Transportation is known in maritime circles as a long-term player operating quality tonnage with a penchant to attract and retain the technical talent it needs. “Support, in the beginning, was a little tough to figure out, but with most OEMs support, we find that we are our best first option,” said Reinauer. “We train our engineers, supply them with all necessary spare parts and only call on their techs for additional support.”

“Some owners run the engine and work through our channel partners for regular maintenance and repairs, focusing their attention on other aspects of running their business,” said Twichell. “Then you have customers like Reinauer that are independent. If one of their engines needs a field modification, Chris Reinauer will say, ‘Just send us the part and instructions, we’ll install it. We know what we’re doing.’”

As anyone running ships can attest, keeping the machinery running is one part of the equation, keeping the machinery running while maintaining profitability is another matter, particularly as fuel prices have spiked in recent months. “We see very good fuel consumption and extremely low oil consumption which is one of the ways they can get to Tier IV emissions without aftertreatment,” said Reinauer. “Serviceability is very good, not as simple as an EMD but they have their advantages in other areas with regards to Tier 4.”

Inside the Wabtec factory. Image courtesy Wabtec

Inside the Wabtec factory. Image courtesy Wabtec

Future fuels and emissions

Reinauer Transportation, like many owners, is faced with difficult choices in regards to choices made today that will impact its costs and operations in the future. Chris Reinauer likes to keep it simple: “As long as the engines we operate are modern and well maintained and our hull forms are fair, there isn’t a more efficient means of transportation. Some people think Zero Emissions are right around the corner but unfortunately, that’s all you hear coming from certain political circles. I agree we need to move forward but batteries are not the answer especially when you consider the energy used to produce them. Hybrid vessels should be used where transits are shorter and local emissions tend to be higher. Ferries are a wonderful application for this as well as ship docking tugs, vessels that are not pulling or pushing 24 hours a day,” said Reinauer. “We on the other hand do not have that luxury and need the most concentrated amount of energy to run at full power for up to a week in some cases. CNG is making inroads but the infrastructure for us to use it is a decade or further away,” citing the lower energy density and the need for larger fuel tanks as primary drawbacks. “We continuously look at the development of alternative fuels, and most likely in the next 10 years we will start implementing (them) somewhere in our fleet.”

Wabtec operates a pair of manufacturing plants in Pennsylvania: one in Grove City, its primary, 440,000-sq.-ft. manufacturing facility, and a sister plant about an hour away in Erie, a facility mostly dedicated to locomotive engine remanufacturing. “Other than castings and forgings, which are sourced, it’s a full manufacturing, assembly and final engine testing plant,” said Twichell. With a cumulative 650 manufacturing employees split between the two plants, Wabtec typically builds about 1,500 engines per year, primarily for locomotive as well as marine.

In addition to engineering a strong product to start, Wabtec fully realizes the power of a qualified dealer partner network, or ‘Channel Partners’ as Wabtec calls them, according to Tamara Gromacki, VP, Marine, Stationary Power and Drill Business. Wabtec monitors its channel partner performance closely, and “if we see that they may be struggling in some service area, Pete Twichell and his team will go in and try to help them increase their skillsets.” Becoming and remaining a Wabtec channel partner is not in perpetuity, as contracts generally run for a year or two, and the renewal process looks at their cumulative skillsets and personnel to ensure that the organization maintains the ability to serve the end customer, remaining “the right fit for Wabtec.”

While the main manufacturing facility has been around since 1971, it’s virtually a new and modern plant courtesy of a 2017 transformation via General Electric “Brilliant Factory” program, with upgraded machinery – including NC machining, laser etching, laser welding, robotic cell and full emissions testing as well – plus new lighting and paint.

With its in-house test beds, Wabtec is able to experiment with a full range of technologies and fuels to ensure that its engines are not only ready to meet the challenges today but to effectively future-proof the engine for changes coming. The future fuel conversation is a pervasive one throughout Wabtec, and according to Hart it breaks down into two groups: one would be biofuels, biodiesel and renewable diesel; the second one would be the lower, no carbon fuels: hydrogen, methanol and ammonia. He said that renewable diesel is the most immediate “drop in.”

“You’ll hear from a lot of renewable fuel suppliers that this will have the most immediate impact, however, it’s quite expensive and needs to be subsidized to be a cost-effective solution. But, for a luxury provider or someone who’s really making a dent in their carbon emissions, it’s a fantastic option,” said Hart. “So, we’re looking at running on 100% renewable diesel, and the biggest interactions there are on the fuel system, the elastomers and filtration, making sure that everything’s going to operate reliably. There definitely are maintenance impacts for some of the biodiesels, and we’re looking at doing the durability testing and the field testing with some of our vessel owners and channel partners to fully validate

Flipping over to the low and no carbon fuel options of hydrogen methanol ammonia, Hart goes back to the real estate axiom of ‘location, location, location,’ noting that choice will be driven largely by where an owner is located and operates and pending the fuel access in specific locales. “Hydrogen seems to be a little bit more conducive to a stationary or land-based access point. Methanol and ammonia seem to be a little bit more what the marine industry is favoring, and what we’re seeing too, is the industry somewhat being fragmented still on what substitution rates want to be included. So, you may not be able to run 100% hydrogen or 100% methanol or ammonia.”

Ultimately, the future fuel question lies outside of the engine room and across the entire vessel, as variable energy densities will demand significant vessel design modifications for tanks and additional machinery. Tug Josephine has a pair of 6L250s. Photo courtesy Reinauer Transportation

Tug Josephine has a pair of 6L250s. Photo courtesy Reinauer Transportation

Keeping the “digital engine” cyber secure

As ship and boat owners increasingly adopt the promise that digitalization promises to deliver – from condition-based monitoring and maintenance and engine and voyage optimization – the potential peril of cyber-attacks must be considered, lest a vessel have its propulsion mains shut down, putting vessel, crew and environment in harm’s way.To that end, the Wabtec team worked diligently to obtain ABS CyberSafety Service Provider Certification.

“Wabtec created a vulnerability report and analysis according to the requirements of ABS CyberSafety Volume 7,” said Mike Taylor, Technical Leader, Marine & Stationary System Engineering, Wabtec. “This report is a comprehensive examination of the control system, listing out access points, the topology or architecture of the system, and an analysis of potential vulnerabilities within the system.”

Wabtec provided extensive documentation regarding internal risk management, policies and procedure, change management and configuration control, as well as details about the Wabtec Incident Response Team, said Taylor. In addition, it designed and presented Cybersecurity Training to all relevant employees. To get the Service Provider PDA with ABS, Wabtec conducted a Type test with the classification society in attendance, as well as a Cybersecurity Audit, to demonstrate that the Wabtec ECS-4 Control System meets the ABS Equipment requirements, according to Taylor. Finally, Wabtec prepared and presented a Cybersecurity Tabletop Exercise, an exercise designed to educate and get participants thinking about potential cybersecurity hazards and courses of action.

“We’re trying to reduce the number of penetration points and make sure that we’re not propagating any part of a cyber security concern as these vessels are extremely complex. The engine is just one piece of it and there are many access points to the vessel to be able to get into the engine. We want to make sure that we try to have a buffer between any other penetration points, which might be available in another third-party system that could potentially penetrate our system, as well. As an example, all our software loading is through a software tool that Wabtec has developed, to get rid of cyber threats through USBs.”